Adiabatic cooling – efficient evaporative cooling with HANSA

Adiabatic cooling, also known as evaporative cooling, is a key component of leading ecological and economic technologies in ventilation system design. This method achieves cooling through water evaporation – entirely without the use of conventional refrigerants. The process utilizes the physical property that evaporation absorbs heat – the air is cooled without requiring additional energy for a refrigeration process.

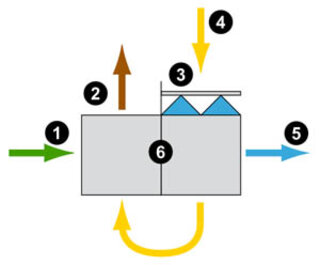

Our HANSA Blue Line ASB+ system implements this principle with a double cross-flow plate heat exchanger.

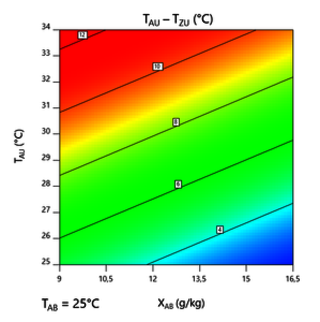

The outside air is cooled by up to 12 K – thus, the recommended temperature difference between outside and room temperature of approximately 6 K can generally be achieved without difficulty.

How does adiabatic cooling work?

When cooling is required, the plate heat exchanger is sprayed with highly atomized water on the exhaust air side. The exhaust air cools down through adiabatic humidification – that is, through heat extraction during evaporation. This cooled exhaust air flows through the heat exchanger and transfers the cooling effect to the incoming fresh air.

The result: effective, indirect cooling without increasing the absolute humidity of the supply air.

This creates a purely adiabatic process in which no heat exchange with the environment takes place – unlike isothermal processes, which operate at a constant temperature. The physical principle: Evaporation extracts energy from the air, lowers its temperature, and provides measurable cooling performance.

Advantages of the HANSA ASB system

- The HANSA ASB system is rigidly mounted and therefore maintenance-free.

- The spray nozzle is positioned parallel to the heat exchanger, ensuring uniform wetting and thus evaporation across the inlet cross-section.

- Optimized water distribution with low consumption.

- No recirculating water, therefore no microbial growth.

- No additional pressure loss.

- We offer an all-in-one solution with independent, cost-effective control and cleaning equipment.

Is adiabatic the same as isothermal?

No.

An adiabatic process is not isothermal because the air temperature changes without any heat being added or released from the outside. Isothermal processes—such as steam humidification—maintain a constant temperature but require an external energy supply. Adiabatic cooling is therefore the more energy-efficient and sustainable method for modern ventilation systems.

Adiabatic humidification as part of cooling

Adiabatic cooling simultaneously utilizes the effect of adiabatic humidification. Water is introduced into the airflow in the form of extremely fine droplets, where it evaporates completely. This process improves air quality, increases energy efficiency, and reduces the need for mechanical cooling. In practice, this results in a dual effect: humidification and cooling in a single system – natural, quiet, and resource-efficient.

Performance and influencing factors

The achievable cooling capacity depends primarily on:

- the temperature and humidity of the outside and exhaust air,

- the efficiency of the heat exchanger,

- the evaporation rate of the water, and

- the design of the spray system.

With the ASB+ system, a temperature reduction of over 12 K can be achieved simply by spraying one side of the double-plate heat exchanger – with minimal water consumption, a robust design, and no additional pressure losses.

Advantages of the HANSA ASB+ system

- Rigidly mounted and maintenance-free

- Planar-parallel spray nozzle for even wetting

- Optimized water distribution with low consumption

- No recirculating water → no microbial growth

- No additional pressure loss

- "All-in-one" solution with independent control and cleaning system

- Robust, efficient, and sustainable

This combination of simple technology and high performance makes adiabatic cooling the preferred solution for modern ventilation systems.

Conclusion

Adiabatic cooling combines physics and efficiency in a natural way. It uses the power of evaporation to cool and humidify without refrigerants. With the HANSA Blue Line ASB+ system, operators receive an energy-efficient, sustainable and durable solution that perfectly combines technology, economic efficiency and ecology.

Adiabatic cooling – efficiency through evaporation.

Request a consultation now

Adiabatic cooling in practice

Our ASB+ system is primarily used in industrial, office, and process ventilation applications. The intelligent combination of indirect evaporative cooling and control technology allows for precise control of air temperatures – even under fluctuating outdoor conditions. This results in an energy-efficient, low-maintenance, and environmentally friendly air conditioning solution.

FAQ: Frequently asked questions about adiabatic cooling

Adiabatic means "without heat exchange with the environment". In air conditioning technology, it describes processes in which water evaporates and absorbs heat from the air – the air cools down without the need for additional energy for a cooling process.

No.

In adiabatic cooling, the air temperature drops through evaporation without heat exchange with the surroundings. Isothermal cooling, on the other hand, operates at a constant temperature – heat is actively removed or added. Therefore, adiabatic cooling is not an isothermal process, but rather an independent physical process.

Finely atomized water is introduced into the exhaust air or a separate air stream and evaporates there. The phase change of the water extracts heat from the air. This cooled exhaust air flows through a heat exchanger and transfers the cooling effect to the supply air stream – without increasing the humidity of the supply air.

Adiabatic means that no heat exchange with the environment takes place. Isentropic additionally means that the process is completely lossless (reversible). In practice, technical processes such as adiabatic cooling are not completely isentropic, as friction and heat losses are unavoidable.

It requires no refrigerants, consumes significantly less energy, and operates virtually maintenance-free. Because it is based on the natural principle of evaporation, it is particularly environmentally friendly and ideal for sustainable building concepts.

The achievable cooling capacity depends on the humidity and temperature difference. Efficiency is lower at high outdoor humidity. Furthermore, the water used should be hygienically treated to prevent deposits and bacterial growth.

The opposite is a diabatic process – a process in which heat is actively exchanged with the environment, for example in classic refrigeration systems with heat exchangers and refrigerants.

With modern systems like the HANSA ASB+ system, temperature reductions of up to 12 K can be achieved – with minimal water consumption and without additional pressure loss.

Adiabatic humidification utilizes the same physical effect as adiabatic cooling: water evaporates, extracting heat from the air and simultaneously increasing humidity. In building technology, both effects are often combined to optimize indoor climate and energy efficiency.