Blue Line

Blue Line: This product stands for highly customisable air handling and full air conditioning units with maximum energy efficiency in the familiar high HANSA quality. These units are configured according to customer requirements in compliance with applicable standards and directives and are optimised for the respective application. Measurement, switching and control technology, DDC programming, integrated refrigeration systems:

We provide you with everything from a single source – optimally adapted to your air handling concept. Units for outdoor and indoor installation, central roof units, units with special section division for retrofitting and upgrading existing systems: no problem with Blue Line units.

Select the basic concept that suits your application from our portfolio:

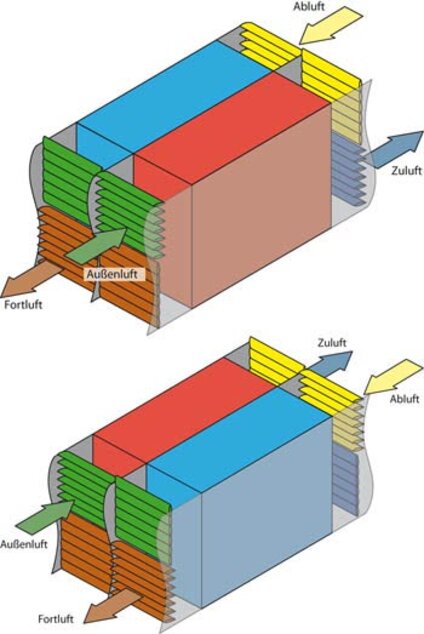

The option of heat recovery with plate exchangers as recuperators is implemented in our Blue Line PT (PT=plate exchanger), Blue Line DPT (DPT=double plate exchanger) and Blue Line GS (GS=counterflow heat exchanger) series units.

As static systems, these recuperators pose no problems mechanically under defined design conditions. In addition, they usually provide adequate separation of the air streams.

Depending on requirements, we install plate heat exchangers with heightened corrosion protection or hydrophilic coatings for special applications.

Plate exchangers made of moisture-permeable materials are available as regenerators.

Blue Line DPT in winter operation

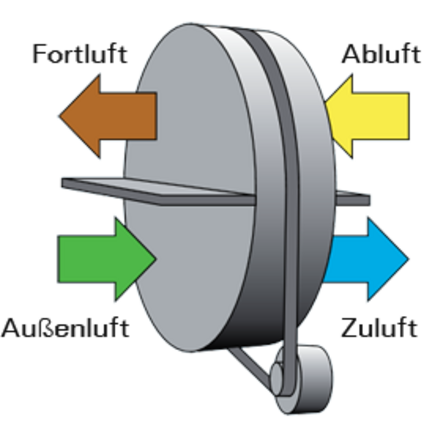

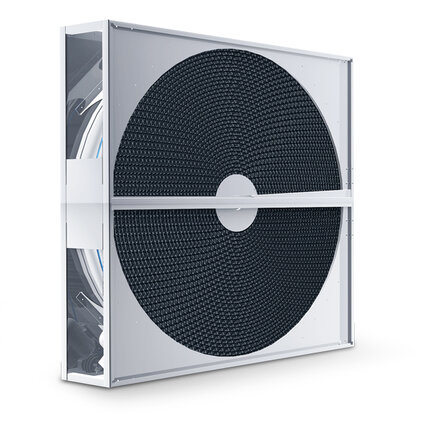

Rotors are used as central energy recovery units in our Blue Line eco-R series.

This is an optimum application area for these components, as high air capacities are required and the exhaust air falls into categories ETA 1 to ETA 3 (see DIN EN 13779).

Your benefits when you choose our Blue Line eco-R system:

- A high degree of efficiency

- Heat and cold recovery

- Moisture recovery in winter

- Continuous controllability

- Low pressure loss

- Tested in accordance with VDI 6022 and DIN 1886

The Accubloc is among the systems with the highest recovery efficiency rates and is the central recovery unit in our Blue Line Accu series.

Outside air and exhaust air are routed alternately through side-by-side storage masses, providing both highly efficient heat and moisture recovery.

Your benefits when using a Blue Line Accu:

- Up to 95 % heat recovery

- Up to 75 % rehumidification

- No freezing

- No condensate drain required

Blue Line Accu units are also individually configured and designed to suit the air conditioning task to be performed.

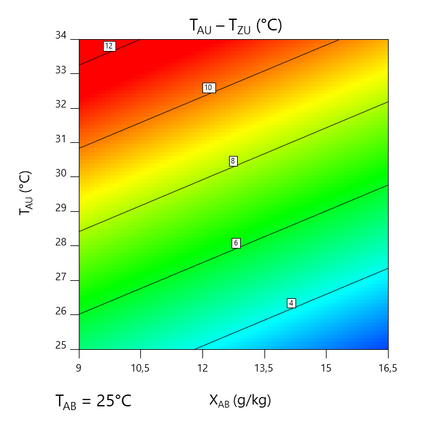

HANSA's Blue Line ASB+ exhaust-air side indirect evaporative cooling system has been a successful model since its introduction. Its investment and operating costs are very low when compared to mechanical cooling, and it allows cooling of the outside air of up to and over 12 Kelvin (see image below).

The HANSA-ASB+ system uses rigidly mounted nozzle assemblies that permit comprehensive and uniform humidification on the exhaust air side of the double plate exchanger used. Combined with increased corrosion protection of exposed components, this means that the system is durable and requires less maintenance.

If separate ventilation units are implemented for supply and exhaust air, or if the air lines have to be separated, heat recovery can take place via the closed-loop system (KVS). The heat transfer medium is a brine, which absorbs and releases heat energy via air-brine registers.

Due to its principle, the KVS is robust against any pressure differences between the air lines and offers a perfect separation of exhaust and supply air. Thus, Blue Line KVS units are mandatory to be used for exhaust air of category ETA-4.

Clean germ-free air is essential for hygienic rooms. Air can be treated according to respective requirements with our Blue Line Hy air handling units.

The desired conditions can be achieved through special filtering processes such as biostatic filters or through UV sterilisation of the air. Thanks to the variable use of secondary units, different hygienic zones can be conditioned with only one central air conditioning unit.

Our decades of experience and the use of sophisticated technologies enable us to adapt each unit precisely to the specific application.

HANSA hygiene units represent a coherent overall concept, thanks to their low noise levels and the use of energy-saving fans.

Standards

- DIN 1946-4 (12/2008)

- VDI 6022, sheet 1 (04/2006)

- VDI 3803 (02/2010)

- DIN EN 13779 (09/2007)

- SWKI VA104-01 (04/2006)

- SWKI 99-3 (03/2004)

- OEN STANDARD H 6021 (09/2003)

- OEN STANDARD H 6020 (02/2007)

All our Blue Line units are individually configured and designed to suit the air conditioning task to be performed. Thanks to our modular HKG design, the series can be individually expanded through the addition of necessary components in each case, including integrated mechanical refrigeration or a heat pump (also reversible), a cold or hot water coil, and humidification, dehumidification and sterilisation units.